Maintenance

The AgnosPCB AI-4050 AOI requires very little maintenance but it is also important for the correct operation of the system.

| Mainteniance | Periodicity |

|---|---|

| Belts tension adjustment | Monthly |

| Cleaning | Monthly |

| Rail guide lubrication | 6 months |

Belts tension adjustment

If you notice excessive belt vibration when the camera moves or the Y-axis carriage is not square to the X-axis, follow the procedure below to tension the belts:

Step 1

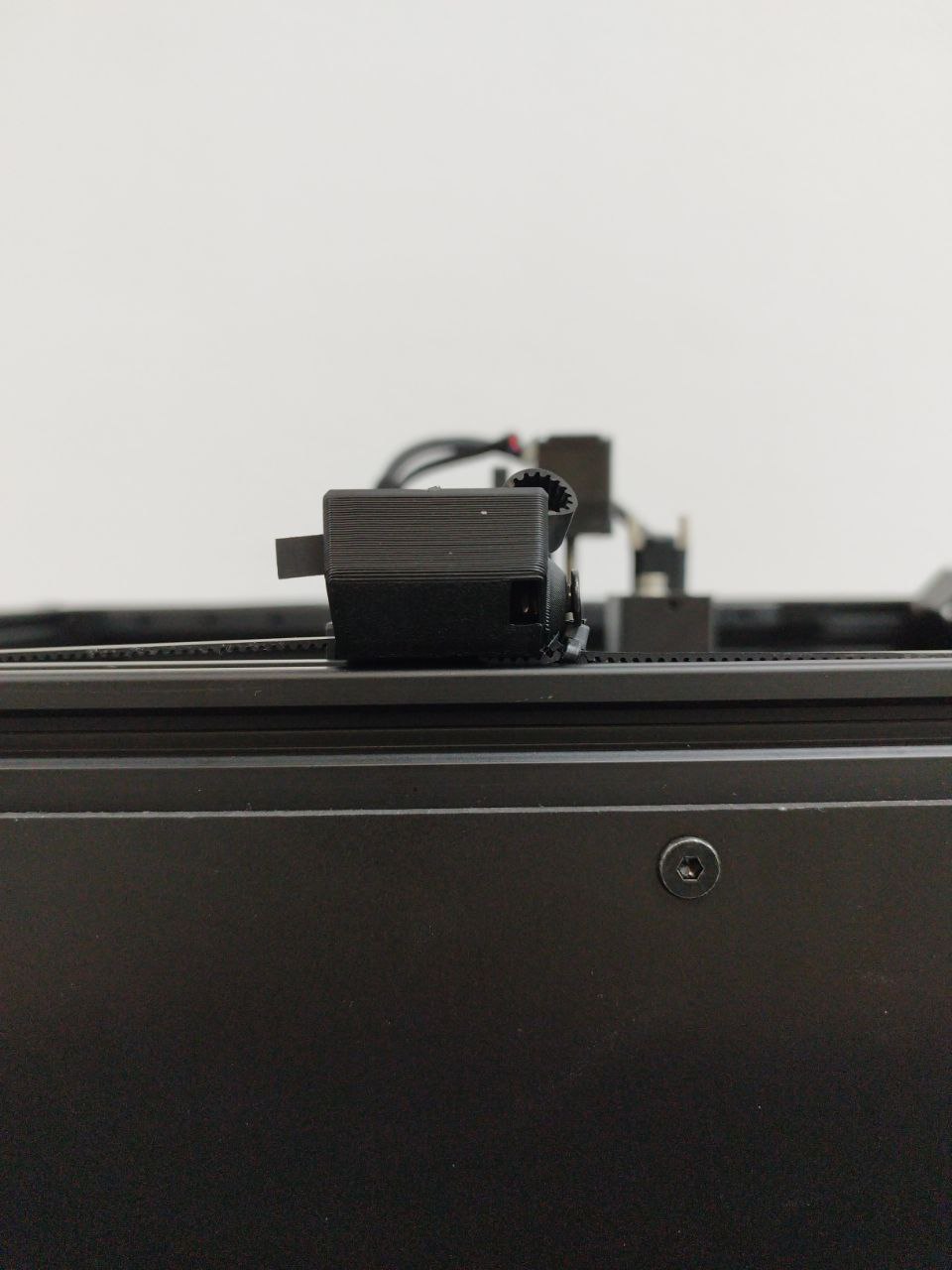

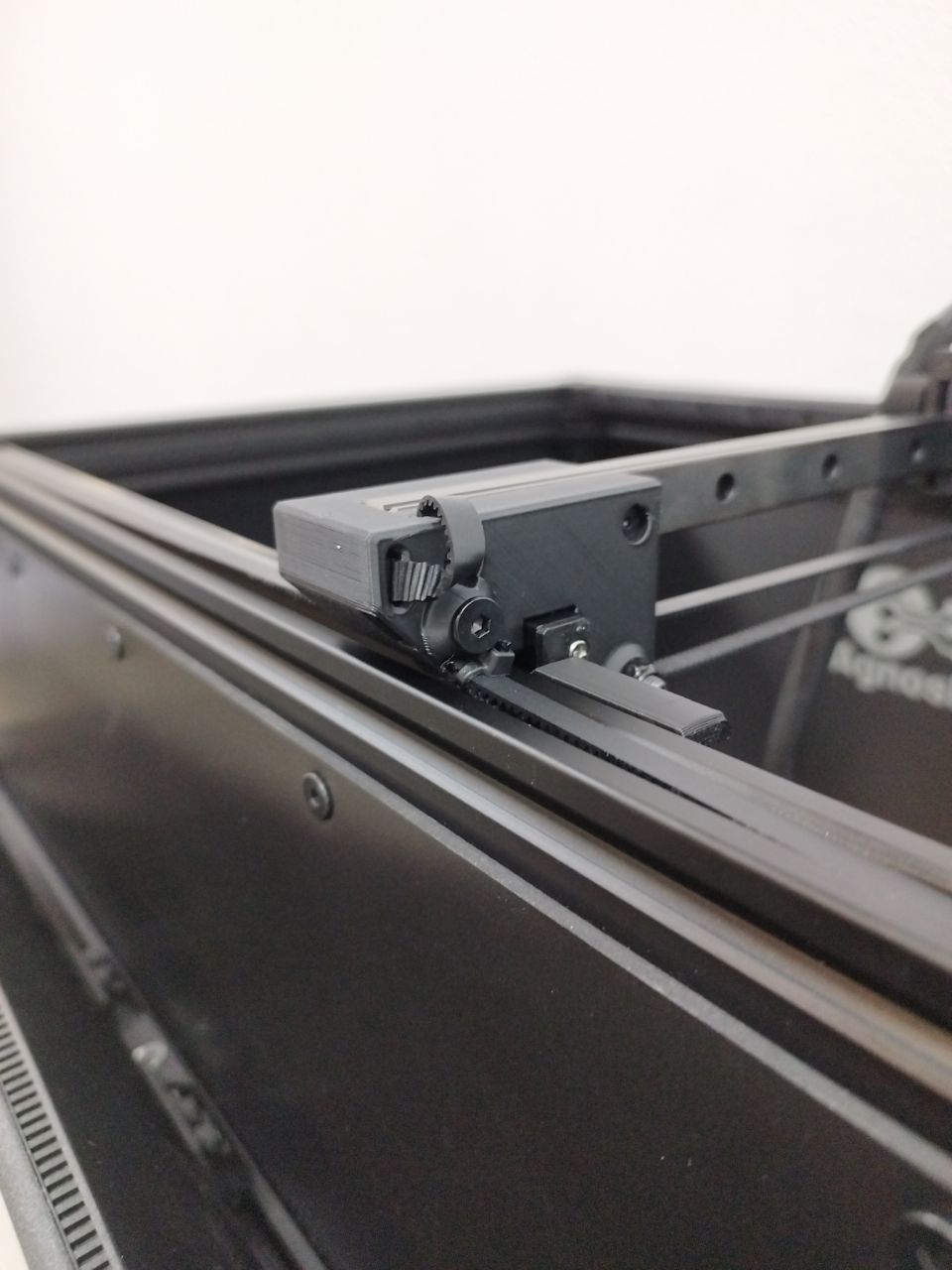

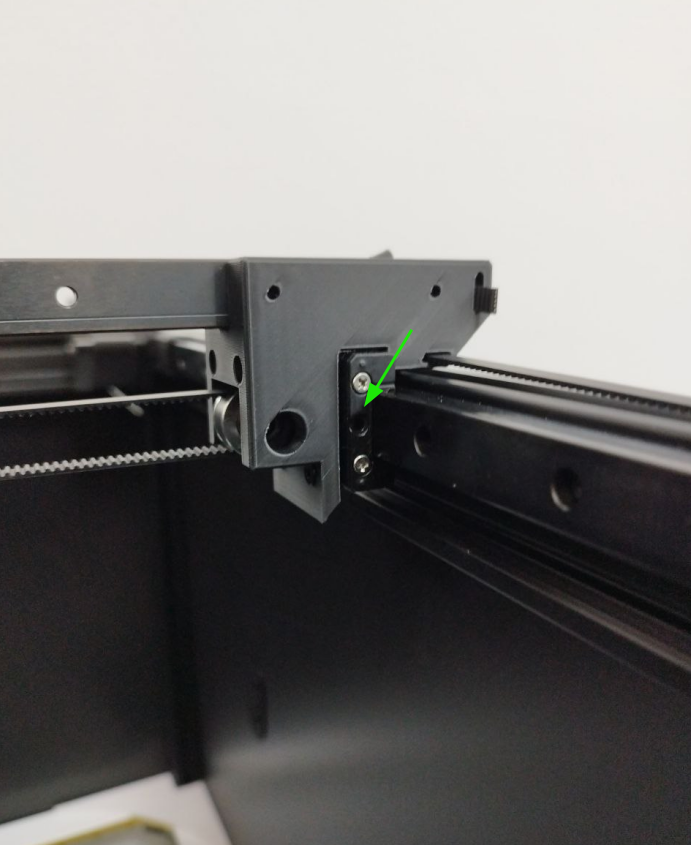

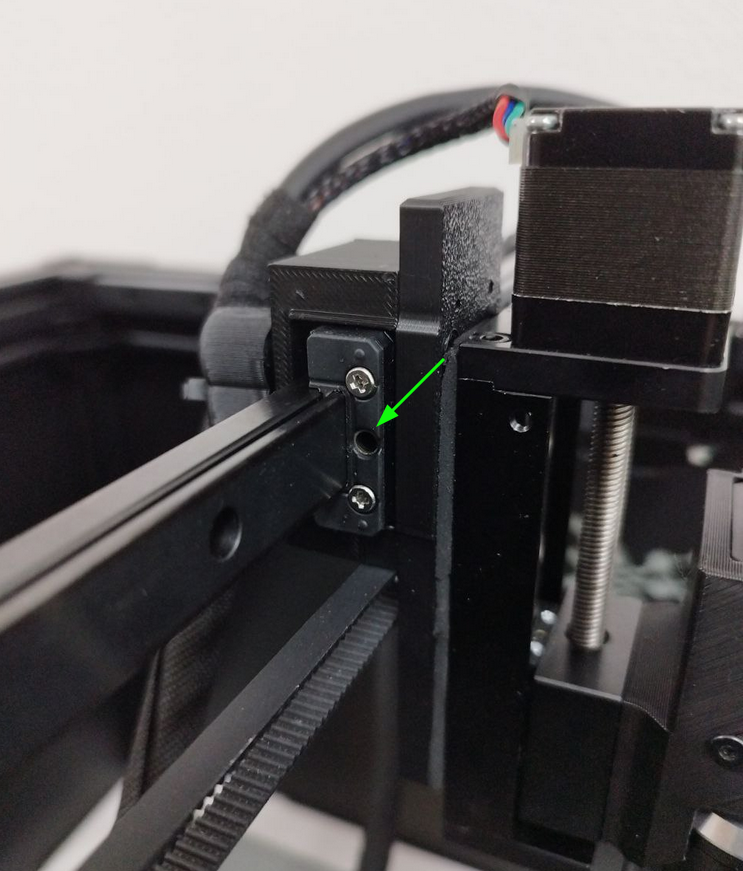

Pull the end of the belt out of the hole.

Step 2

Loosen the hex screw enough to be able to pull the belt.

Step 3

Pull the belt until it is straight and taut along the entire length of the rails.

Step 4

Tighten the screw to secure the belt in place.

Step 5

Insert the end of the belt in the hole

Step 6

Repeat the steps 1 to 5 for the other rail if necesary.

Cleaning

Warning

Do not use any liquid cleaner, alcohol or degreaser on moving parts (rails, carriages, spindle, etc...) or electrical components.

Step 1

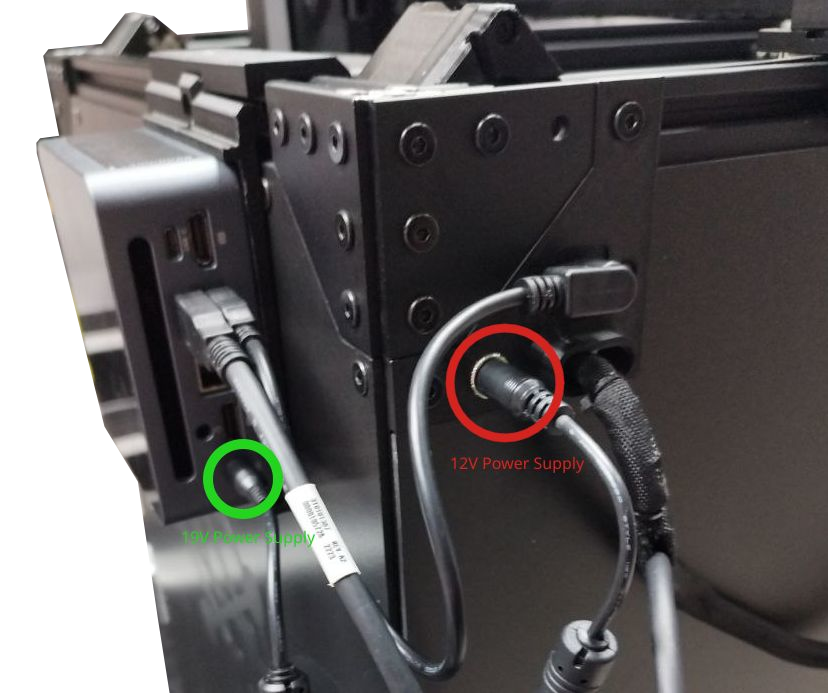

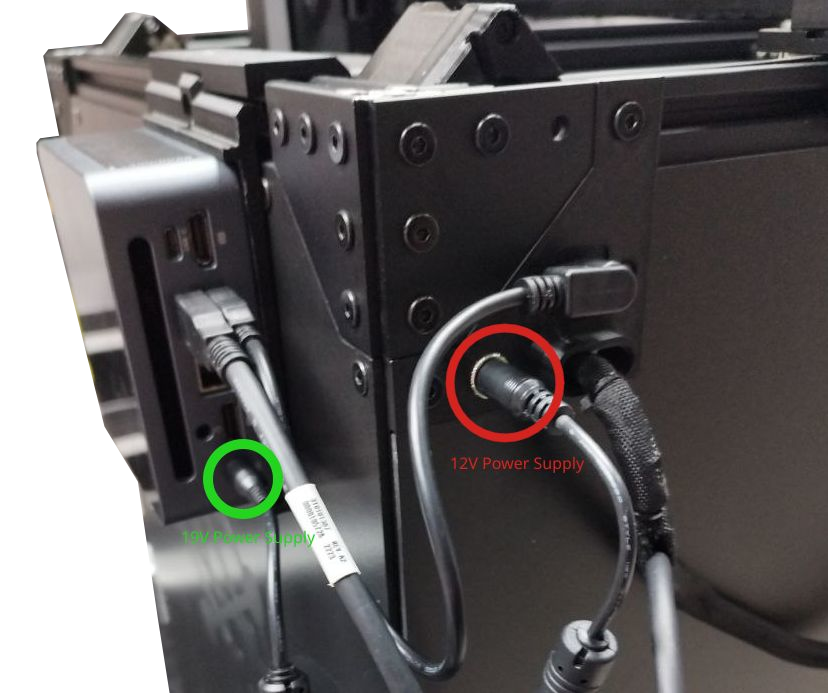

Disconect the power supply or AC cord from the rear panel of the machine.

See red:

Step 2

Use a napkin or cotton swab to remove the old grease from the lineal rails.

Step 3

Use the brush provided in the maintance kit to remove any contamination inside of the rails.

Step 4

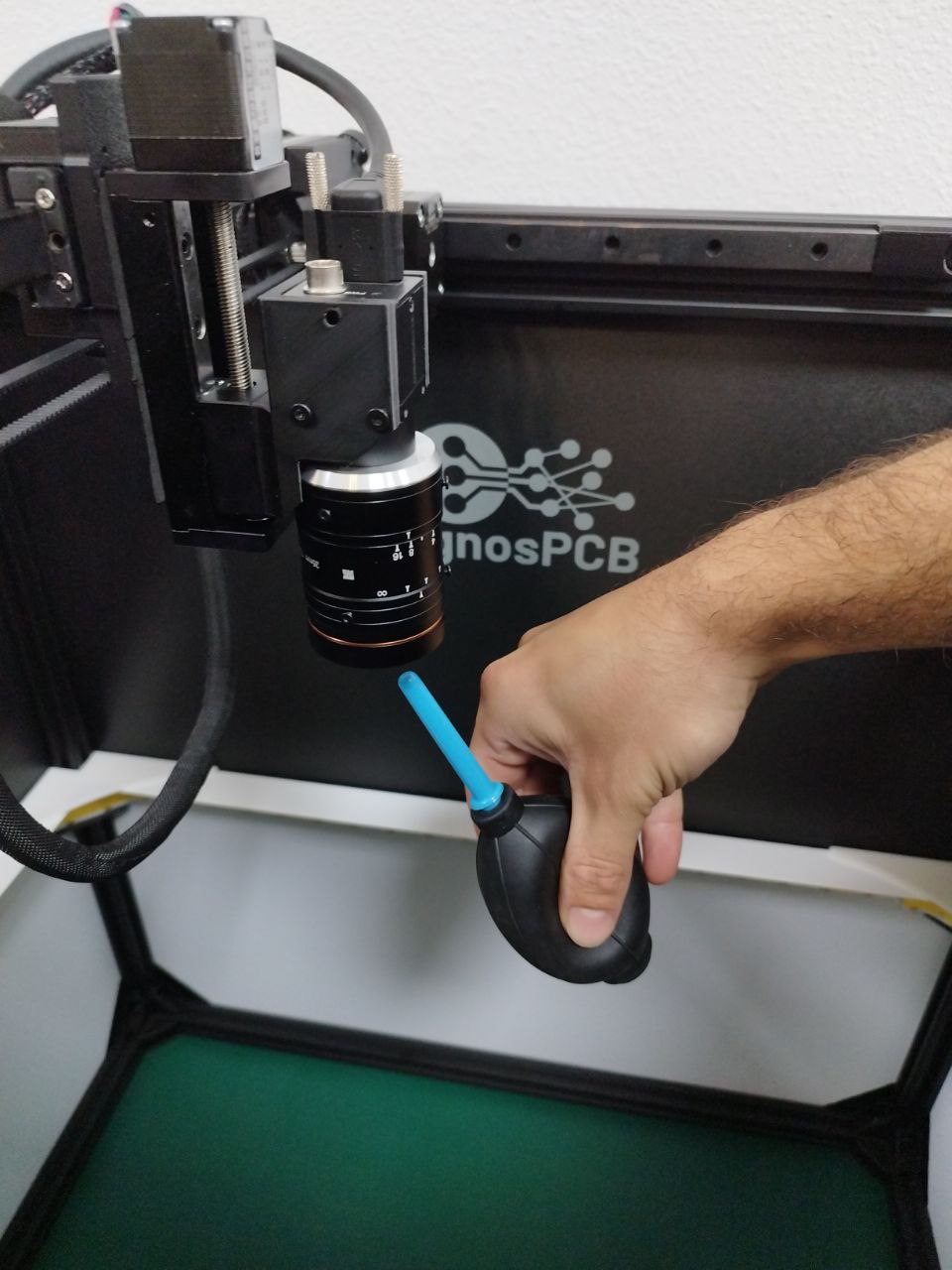

Use the air blower included in the maintenance kit to blow the camera lens and remove any debris.

Note

Optionally, you can clean the lens with a microfiber cleaning cloth after using the blower, as there may be particles that could scratch the lens.

Rail guide lubrication

Warning

Before lubricating the carriages, be sure to clean the rails.

Step 1

Disconect the power supply or AC cord from the rear panel of the machine.

See red:

Step 2

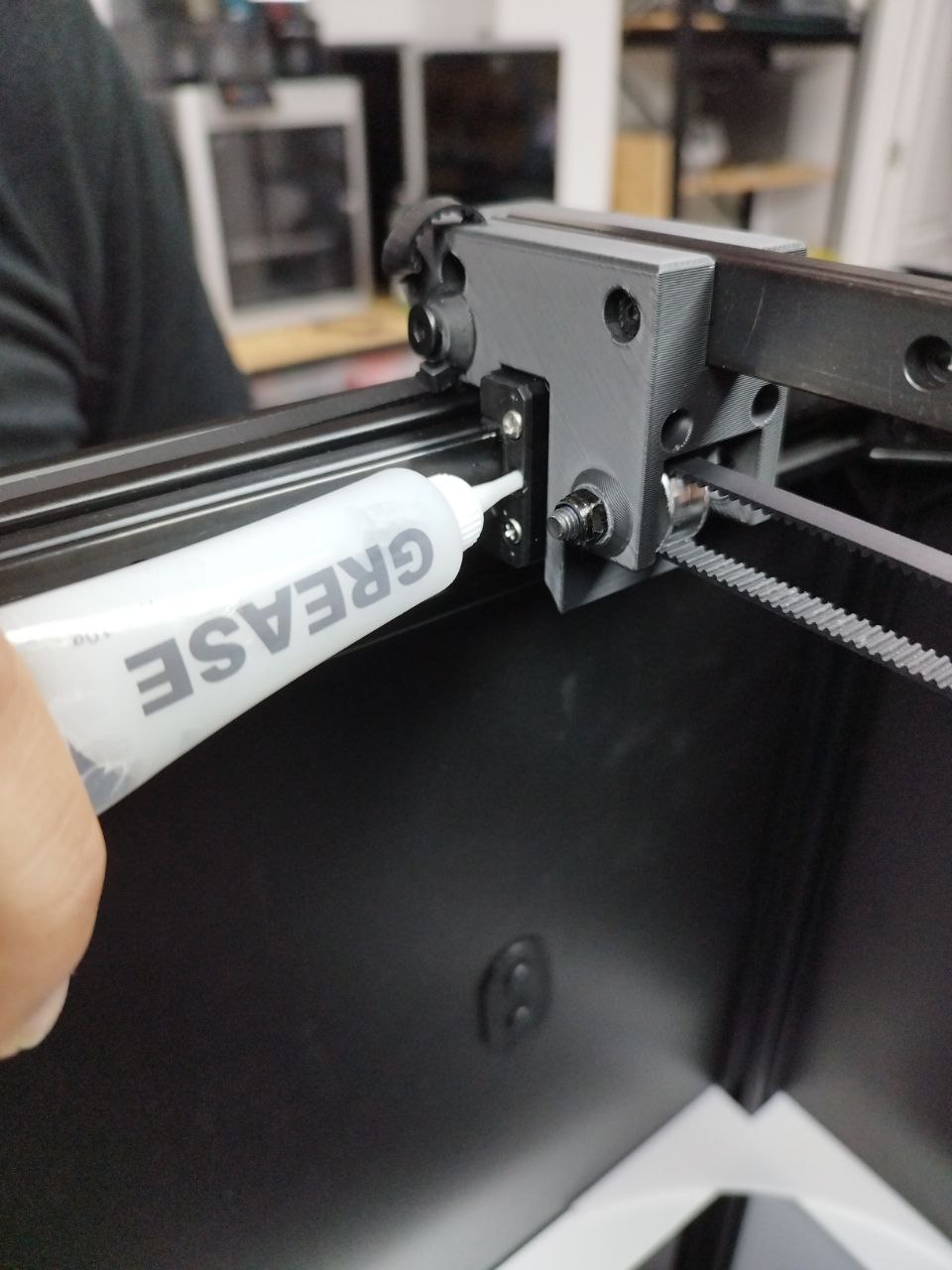

Insert the end of the grease dispenser provided in the maintance kit into the hole on the side of the rail carriage.

Step 3

Apply a little grease to the carriage.

Step 4

Move the carts manually to distribute the grease along the rails.

Step 5

Connect the power supply or AC cord to the platform.